Air of Authority - A History of RAF Organisation

No 40 Group Equipment Storage and Supply

The following is extracted from Chapter 8, AP3397 'Maintenance' (AHB - 1954)

The Formation of the Mechanical Transport Companies, 1940

No radical changes took place within No 40 Group during 1940. A universal supply system was further developed and Nos 1 and 4 Maintenance Units (whose remaining functions were not generally within the scope of No 40 Group) were transferred to No 43 Group, Maintenance Command. It was decided, however, to form 'M' and 'P' Maintenance Units at Kidbrooke and Ruislip respectively to absorb the No 40 Group functions hitherto carried out by parts of Nos 1 and 4 Maintenance Units. The 'H' Maintenance Unit, Dumfries, transferred its holding to Carlisle and took over the issue of barrack equipment and clothing. Nos 1, 2 and 3 Mechanical Transport Companies were formed within the Group and located at Darlington, Cambridge and Ightham respectively.

The Revision of the Stockholding Policy at Equipment Depots

As a result of the large quantities of stores which were beginning to be delivered off war contracts by the autumn of 1940, it became necessary to acquire additional storage accommodation in each of the six geographical areas served by the universal equipment depots. This accommodation, which consisted of suitable requisitioned buildings, was needed to store the low priority sections of equipment and also the overflow of equipment from other sections of higher priority, thereby relieving the growing congestion in the depot sheds and permitting greater dispersion of valuable stocks.

A conference was held at Headquarters, No 40 Group on 3 October 1940, at which Air Ministry were represented, to decide what alterations to the stockholding policy would be necessary and also to lay down the future organisation of the existing lettered maintenance units and newly acquired depositories. The following proposals were agreed to

(a) To establish in each of the geographical areas a sell-contained stores accounting unit to hold the barrack and clothing ranges of equipment and thereby relieve the universal equipment depots of handling and accounting for any of these types of stores. Consumers' demands and serviceable surplus returns were to be sent direct to the appropriate maintenance unit holding the range of this type of equipment.

(b) A full range of equipment in the remaining sections would be held in each UED except at Milton, and any overflow from these sections would be stored outside in any vacant space in the depositories. Equipment so housed would remain on charge and under the complete control of the UED depositories, other than those established as self-contained units for barrack and clothing stores, which would be controlled as overflow sites of the local UED

(c) Owing to the limited accommodation at No 3 Maintenance Unit, Milton, it would be necessary, as an exception to the above proposals, to establish 'B ' Maintenance Unit, Hammersmith, as a self-accounting unit for a range of equipment sections in excess of barrack and clothing equipment.

(d) With the exception of Hammersmith, all depositories, including properties requisitioned for storage, would be under the Regional Universal Depot Commander for the purposes of all major administration, i.e. matters of Works Services, defence and discipline.

It was agreed by Air Ministry that action should be taken immediately to introduce the new organisation in anticipation of their eventual approval.

As regards the two new self-accounting units to be formed in the Stafford and Heywood areas for barrack and clothing equipment, it was proposed to use the requisitioned properties known as 'Sheffield' and 'The Great World Stores, Manchester,' respectively. These would be known as 'Q' and 'E' Maintenance Units and details of their establishments, etc., were submitted in due course.

Broadly speaking, the following units were under the jurisdiction of No 40 Group at the end of 1940: -

Six Universal Equipment Depots.

Six Barrack and Clothing Depots.

Three Mechanical Transport Companies.

Eight Miscellaneous Units.

Further expansion took place during 1941, the most notable feature being the introduction of the equipment parks and an internal reorganisation resulting in the formation of the universal equipment wings.

The Introduction of the Equipment Parks

During 1940 considerable experience had been gained of delays to which rail and postal services were subject as a result of air attack, and although only one area may have been the object of the attack the interruptions to communications were found to be both widespread and cumulative. The results of a possible intensification of this enemy air attack were therefore viewed with considerable misgivings.

A further aspect which gave some cause for concern was the heavy retail load imposed on the supply system by stations demanding direct on the depots. At that time there were 478 RAF units all demanding separately and each item was dealt with as one transaction throughout the process of supply. The system was already creaking beneath the strain imposed on it by the depots and by the Master Provision Office (MP0) having to handle so many piecemeal demands from consumers. With the projected expansion of the Royal Air Force it was difficult to see how efficiency could be maintained unless demands were 'rolled up' in some way so as to reduce the number of separate transactions. Ten separate demands for one item took almost ten times as much time and labour to deal with as one demand for ten times the quantity. In these circumstances it therefore seemed that the existing supply system was not altogether suited to the changed conditions of warfare in the United Kingdom; and that furthermore, with such long lines of communication and the increasing number of stations which would have to be supplied, there was liable to be a real danger of a breakdown followed by a further loss of efficiency due to the introduction of extemporised measures.

The problem, therefore, was how to improve this position without making the supply organisation too complicated, and with this end in view the following proposals were evolved: -

(a) To form stores holding parks located forward with the operational units and to call them equipment parks.

(b) To supply the parks by bringing forward a portion of the available stock then held at depots, whilst at the same time absorbing some of the stock authorised to be held at stations. The parks would be required to stock only airborne stores, as other stores were common to all stations and speed of supply was not of paramount importance. The suggested stock establishments for the parks were three months maximum and two months minimum of the airborne sections of stores.

(c) The parks were to maintain stocks by submitting monthly to the parent depot a statement showing the stocks required to bring them up to the maximum, regardless of whether the minimum had been reached. The depot would issue against this statement as stocks became available throughout the month, but would not take inability action. The statement would be closed and superseded on receipt of the next monthly statement. Any item which had not been supplied by the depot against the previous month's statement would not be regarded as 'due in ' when compiling the current statement.

(d) If a park could not issue to stations because it was out of stock of the item or the item was new, the park could demand direct on the Master Provision Office (MPO) to cover its outstanding commitments plus a reasonable quantity to cover consumption until the end of the month. Any demands so placed would be regarded as 'due in' and would be discounted on any subsequent demands to the MPO and also on the monthly statement to the depot.

It was claimed that the introduction of the above proposals would reduce delays on demands for short stock items on the MPOs, save three to four days in supply, provide a daily supply of all available items to units and reduce the number of transactions at the Universal Equipment Depots (UEDs). As the bulk would be taken further forward this would save much piecemeal issuing at UEDs. With a reduction in labour and transport the UEDs would handle no inabilities for operational units, whilst there would be a reduction in abilities on stock demands handled by the MPOs. The centralisation of stocks at the parks would permit a reduction in the stocks of items seldom used by the squadrons, without seriously reducing their availability, an availability which could now be more easily extended to other areas in the event of an emergency.

It would also increase the dispersion of stocks from the UEDs and the consumption would be reflected in the provisional records earlier on account of the bulk issues made to the parks.

At a meeting held at the Air Ministry on 27 March 1941 it was agreed to recommend that two or three of these equipment parks should be formed on an experimental basis. Perth and Inverness were accordingly selected and they were required to supply equipment in the airborne ranges to 14 and 8 operational stations respectively. No 17 Maintenance Unit, Perth, and No 79 Maintenance Unit, Inverness, were formed in June 1941, and these were followed by No 74 Maintenance Unit, Bough Beech, No 87 Maintenance Unit, York, No 203 Maintenance Unit, Newark, and No 204 Maintenance Unit, Rushton. No 44 Maintenance Unit, Holywood, had previously been established to meet supply difficulties in Northern Ireland. Further parks were opened in 1942 and 1943 and details of the formation of these appear later.

Miscellaneous Units

A marine craft storage unit was formed at Dumbarton during the year and was designated No 62 Maintenance Unit, and a mechanical transport storage unit, No 99 Maintenance Unit, was formed at Derby, in ex-Balloon Command accommodation.

No 4 Mechanical Transport Company, London (MT Company), was transferred to No 40 Group and Nos 5, 6, 7 and 8 MT Companies were formed within the Group during the year. 'C' Maintenance Unit, Coventry, which was completely destroyed by enemy action during November 1940, was finally disbanded during March 1941. No 61 Maintenance Unit (in the 'projected stage' this was known as No 57 Maintenance Unit) the seventh and last of the Universal Equipment Depots was formed in July 1941 and progressively assumed an issue load. This resulted in a further variation in the dispersal policy and adjustment of the regional areas.

'M' Maintenance Unit, Kidbrooke, and 'P' Maintenance Unit, Ruislip, ceased to exist as separate units in August 1941, and the responsibility for their administration was transferred to 'A' Maintenance Unit, Wembley. Similarly, 'A' Maintenance Unit absorbed the functions of 'B' and 'D' Maintenance Units.

'G' Maintenance Unit, Norwich, and 'L' Maintenance Unit, Salford, were also disbanded. 'F 'Maintenance Unit was transferred to Kettering with effect from 13 October 1941, and 'K' Maintenance Unit, Shepton Mallet, was transferred to the Ministry of Aircraft Production.

The Formation of the Universal Equipment Wings

Since its inception No 40 Group had been rapidly expanded as regards both the number of units which it had to control and the extent of its responsibilities. By February 1941 the Group comprised 20 self-accounting units and a large number of hired premises which were used for overflow stocks. Of these, 16 were directly controlled and administered by Headquarters, No 40 Group, the other four being administered by the Group and controlled operationally by the Air Ministry. The strength of the Group was 450 officers, 4,700 other ranks and 16,600 civilians. Numerous other units were either under construction or contemplated.

Owing to this rapid growth and the magnitude of the work undertaken it had become increasingly difficult to administer and control so many units from a Group headquarters. This situation was further accentuated by the widely dispersed location of the units and the impaired travelling facilities and communications. In these circumstances it was becoming impossible for the Group Commander to keep in sufficiently close touch with units, so as to ensure uniformity and a high standard of efficiency. Much of the time of his staff was spent in travelling long distances on visits of inspection and supervision.

A stage had therefore been reached which demanded the introduction of some measures of relief of the direct control of units by the Group headquarters. What was required was a strengthening of the administrative side of the headquarters, coupled with a reduction in the number of units directly controlled and the decentralisation of functional supervision to staffs in closer contact with the units.

The strengthening of the administrative staff at Group headquarters would leave the Senior Maintenance Staff Officer with the functional control of the Group and enable the Group Commander to devote more time to the operational and maintenance problems.

With regard to the decentralisation of functional supervision from Group headquarters it was considered that there were two alternatives, both of which would strengthen the Group and reduce the number of contacts. These were as follows: -

(a) To establish three wing formations located in the Northern, Midland, and Southern Areas, each of which would be directly responsible to Group headquarters for functional supervision and defence of all the units in their area; or

(b) To reorganise the Universal Equipment Depots (UEDs) into Universal Equipment Wings, each wing being responsible to the Group for the functional control and administration of its own UED and also the other units in its area.

These two proposals were submitted to the Air Ministry by Maintenance Command with a request that approval be given for the adoption of three independent wings as outlined in (a) above.

The Assistant Director of Organisation Establishments (ADO Est.) visited Maintenance Command and discussed the proposals at great length. There appeared to be two main difficulties, first, the problem of geographical dispersal, and secondly, that the commanding officers of the Universal Equipment Depots were found to be too overburdened to assume responsibility for the detached barrack and clothing sites at the lettered maintenance units in their zone.

It was thought that it would be extremely hard to maintain in practice the division between functional and administrative control and that the wings under the three wing organisation would be bound to grow and the chain of control might become 'post officed'. The second alternative proposal was the one favoured by Air Ministry, and it was therefore decided to hold an establishments committee meeting to decide exactly what should be done. They reached the conclusion that it would not be satisfactory to interpose wing formations, particularly as, in their opinion, they would tend to lead to delays and waste of personnel. Instead they considered that the UEDs should be suitably strengthened so as to relieve the commanding officer and allow him to exercise a general supervision over all the units in his area for which he would be responsible.

The original proposals were subsequently reconsidered by the AOC, Maintenance Command, and the AOC, No 40 Group, in the light of the committee's suggestions, and revised proposals were put forward on that basis. These were subsequently approved by the Director General of Organisation and came into operation on 1 June 1941. Under this scheme the universal equipment depots assumed responsibility for the administration of the units within their area as follows: -

| UED |

Responsible for |

| No 3 MU | 'A, 'B', 'D', 'M' and 'P 'Maintenance Units: Nos 3 and 4 MT Companies. |

| No 7 MU | 'E' Maintenance Unit |

| No 14 MU |

'H ' and No 55 Maintenance Units: Nos 1 and 6 MT Companies. |

| No 16 MU |

'F' and '5' Maintenance Units. |

| No 25 MU | No 2 MT Company. |

| No 35 MU | 'L' and' R' Maintenance Units: Nos 5 and 7 MT Companies. |

In this connection it was decided that 'A' 'B,' and ' D' Maintenance Units should be telescoped to form one unit, to be known as 'A' Maintenance Unit, and proposals for a revised establishment were prepared. Similarly, 'L' and 'R' Maintenance Units were telescoped to form' R 'Maintenance Unit. It will be observed that the MT Companies were placed geographically under the appropriate UED for the purposes of administration.

The title of 'Universal Equipment Wings' was later changed to that of 'Wing Maintenance Units' and this organisation remained in operation until November 1944, when it was disbanded and three regional wings were formed. The details of the regional wing organisation are included later.

|

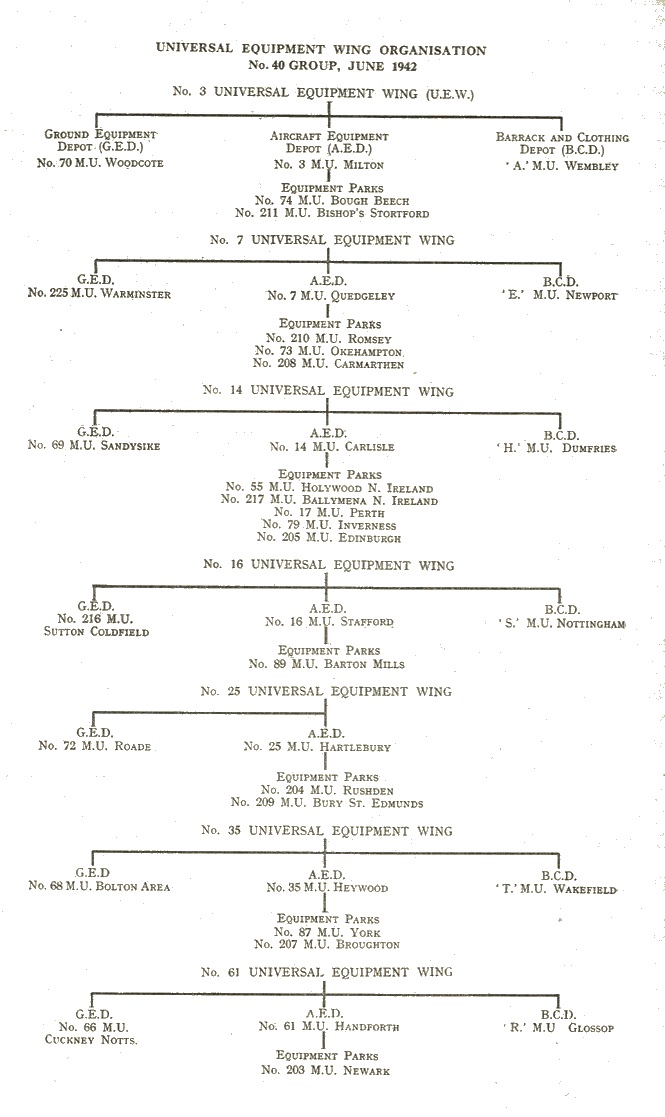

| Diagram 16 |

|

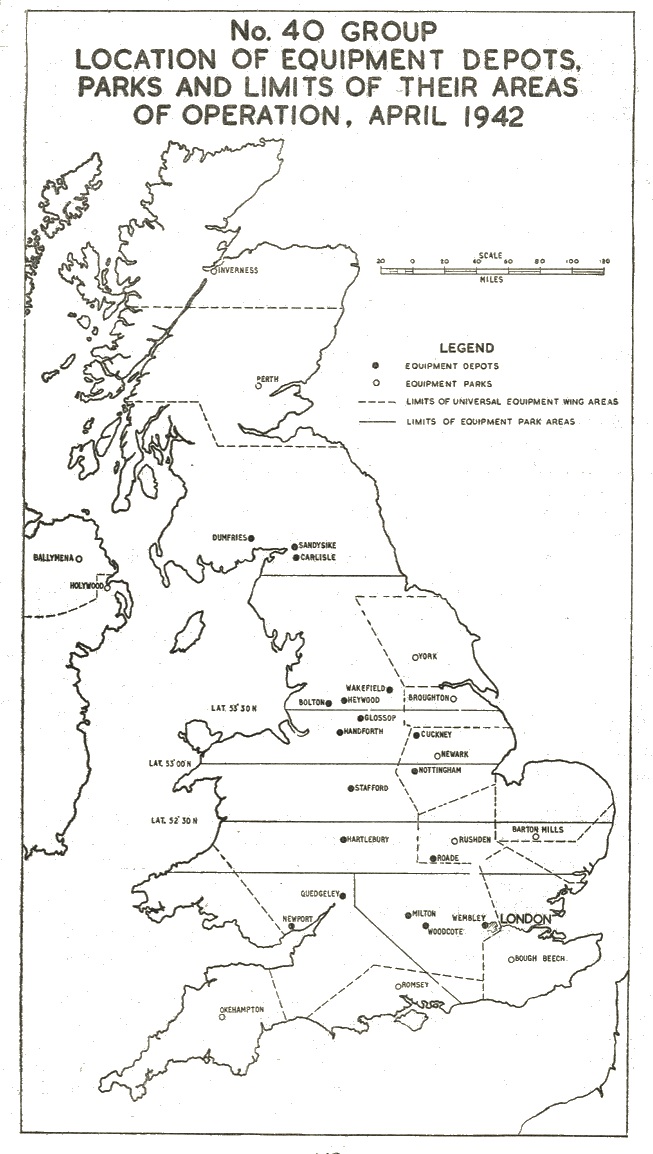

| Diagram 17 |

The Formation of the Ground Equipment Depots

The main feature of 1942 was the formation of six ground equipment depots (GEDs) which were located as follows: -

| GED | Location | Formed |

| No 66 MU | Cuckney | 1 March 1942 |

| No 68 MU | Bolton | 23 May 1942 |

| No 69 MU | Sandysike | 1 March 1942 |

| No 70 MU | Woodcote | 1 March 1942 |

| No 72 MU | Roade | 1 March 1942 |

| No 216 MU | Sutton Coldfield | 1 August 1942 |

These ground equipment depots (with the exception of Nos 68 and 216 Maintenance Units) were originally planned as equipment dispersal depots (EDDs), each with a total of 240,000 super feet of storage accommodation in 32 sheds, each 150 ft x 50 ft. It was intended that stocks at the equipment dispersal depots should be held on deposit to the main stock records kept in the affiliated universal equipment depots, but the equipment dispersal depots were not intended to receive demands direct from external sources.

It was apparent, however, that the universal equipment depots themselves required further relief from their retail loads, and after reconsideration it was decided to reverse the policy in regard to the equipment dispersal depots so they would be in a position to assume full responsibility for the receipt, storage and issue of items in the following sections: -

| Section 1 | Tools |

| Section 3 | Machine Tools, Spares and Accessories |

| Section 13 | Drawing Instruments. |

| Section 16B, E, G and H | Marine Craft and MT Stores and Tools |

| Section 17 | MT Spares |

| Section 18 | Marine Craft Spares |

| Section 29 | General Hardware. |

| Section 30A and B | Metals |

| Section 32A, B and C | Cordage, Textiles and Rubber |

| Section 33 | Paints, Dopes, Chemicals, etc |

| Section 41 | Marine Craft Spares |

| Section 43A-R | Mobile Crane Spares |

| Section 53 | Spares for Specialist Vehicles |

These depots, then renamed ground equipment depots, were made fully self-accounting units and served the same geographical areas, in respect of their range of equipment, as the universal equipment depots in whose wing areas they were located. The initial stocking-up in respect of Nos 66, 69, 70 and 72 Maintenance Units was effected by stock transfers of the appropriate sections of Nos 16, 14, 3 and 25 Maintenance Units, the transfers being carried out in two phases. As soon as 50 per cent of the stock in any one section had been transferred to the ground equipment depot, the ground equipment depot assumed the issue load.

The change in policy in respect of the first four ground equipment depots necessitated some variation in the accommodation already under construction. The depots were designed merely to hold bulk stocks, but on their assumption of responsibility for detailed issues it was necessary to provide additional transportation facilities, heating, windows, offices and signals facilities. No 216 Maintenance Unit was formed on 1 August 1942, the ex-Balloon Command accommodation at Sutton Coldfield being taken over for this purpose.

In June 1942 depots which had hitherto been known as universal equipment depots (UEDs) were renamed aircraft equipment depots (AEDs) and the newly formed GEDs (sometimes referred to as general equipment depots) were designated ground equipment depots, although their function was to hold-general equipment in the known airborne ranges. The barrack and clothing depots retained that title and the abbreviation of B and CD

The Development of the Static Equipment Parks

Eight further static equipment parks were opened during 1942 as follows: -

| SEP | Location | Formed |

| No 217 MU | Ballymena | 1 March 1942 |

| No 205 MU | Edinburgh | 15 May 1942 |

| No 210 MU | Romsey | 8 June 1942 |

| No 73 MU | Okehampton | 15 August 1942 |

| No 208 MU | Golden Grove | 15 August 1942 |

| No 207 MU | Retford | 5 September 1942 |

| No 89 MU | Barton Mills | 15 October 1942 |

| No 211 MU | Sawbridgeworth | 20 December 1942 |

These parks were designed to hold equipment in the appropriate airborne ranges.

The Formation of the Mobile Equipment Parks

In June 1942 proposals were submitted by Headquarters, No 40 Group to provide for the formation of mobile equipment parks which it was maintained would be required: -

(a) In the event of an invasion involving the rapid disposition of squadrons, with possible disruption of the normal channels of supply from static equipment parks.

(b) To support squadrons forming the air contingent of an expeditionary force.

In either situation it was important, if operations were to be maintained, that the distributing units supporting the squadrons should be well organised and thoroughly efficient when called upon to fulfil their role. At that time squadrons would have been served by hurriedly organised units, designated as air stores parks, who would have had little or no knowledge of the problems with which they would have been faced. In these circumstances, therefore, it was maintained that there was every justification for the early formation of mobile air stores parks, to be equipped with the types of aircraft the parks would be called upon to maintain either in the event of an invasion or to support an expeditionary force in the field.

In July 1942 Headquarters, Maintenance Command submitted proposals to the Air Ministry to provide for the formation of two mobile equipment parks to be located in the proposed supply areas of No 73 Maintenance Unit, Okehampton and No 89 Maintenance Unit, Barton Mills. These units would not have been in a position to commence operations for some months, owing to the delay in the provision of accommodation. It was suggested that the holdings of the parks should be limited to the technical range and should comprise a three months maximum and a two months minimum stock. They were to be fully mobile and sell-contained so that they could operate in the same manner as if they were actually in the field.

The approval to commence the formation of the two mobile equipment parks was received early in August 1942. A total of 700 other ranks was trained at these parks which were ultimately transferred to No 83 Group, Allied Expeditionary Air Force, in 1943. The formation of further mobile air stores parks was undertaken by No 40 Group, and details of these are given later.

The Barrack and Clothing Organisation and the Formation of No 55 Wing

The 'T' Maintenance Unit at Wakefield was formed in May 1942, and was the sixth and last barrack and clothing depot to be established. These six depots were to serve the seven universal equipment wing areas, but, in spite of repeated attempts, efforts to obtain suitable hirings in the Hartlebury area proved unsuccessful. Nevertheless it was essential that the range of barrack equipment and clothing then accommodated at Hartlebury should be removed, in order that the storage space could be made available for technical stores.

It was considered that there was no fundamental reason why the barrack and clothing areas of supply should coincide with those of the universal equipment wings, and in view of the fact that it was necessary to arrange barrack and clothing depots in areas where properties were being made available by the Board of Trade, and not necessarily in the localities most conveniently placed for No 40 Group holdings, to attempt to fill the universal equipment wing supply lines would frequently be inconvenient and uneconomical. Accordingly, authority was sought to split the country into six areas for the supply of barrack equipment and clothing. This was agreed and implemented with effect from 16 June 1942, and simultaneously the contract deliveries of these stores ranges to No 25 Maintenance Unit ceased and the holdings at that universal equipment depot were dispersed.

The organisation in respect of the barrack and clothing depots was finalised by the formation of No 55 Wing at Derby on 1 August 1942. The new wing headquarters was responsible for the administration of all barrack and clothing depots within No 40 Group, i.e. 'A,' 'B,' 'H,' 'R,' 'S 'and 'T' Maintenance Units, for all matters affecting these depots, and for interpreting No 40 Group policy at wing level. This organisation remained in operation until the regional wings assumed control in November 1944.

Miscellaneous Units

No 210 Maintenance Unit at Poynton opened with effect from 16 March 1942, and operated as a centralised overseas bond. This unit occupied accommodation originally constructed for No 61 Maintenance Unit under whose jurisdiction they came, No 201 Maintenance Unit being self-accounting for stores only.

No 232 Maintenance Unit, White City, was formed within No 3 Wing in September 1942, the new unit assuming responsibility for the undermentioned commitments hitherto carried out by 'A' Maintenance Unit, Wembley. The barrack equipment in store at White City was accordingly transferred to 'A' Maintenance Unit at Wembley.

Mechanical Transport Reception Depot,

Section 4 of Ground Equipment,

Section 6D, Gas Cylinders,

Section 16G, Moorings (pending completion of transfer to No 4 Maintenance Unit).

Nos 1, 2 and 3 Canal Clearing Depots (CCDs), at Paddington, Birmingham and Manchester respectively, continued to operate throughout the year. Where possible the contractors, who were normally within 10 to 25 miles of the depots, were instructed by the relative Master Provision Offices to effect deliveries to maintenance units via the canal clearing depots. The equipment so transported was unloaded at convenient locations for subsequent collection by maintenance units. This method provided notable relief in the already congested railway sidings at the depots, and during 1942 the following tonnage was shipped by the CCDs

| No 1 CCD Paddington | 5,049 tons |

| No 2 CCD Birmingham | 5,181 tons |

| No 3 CCD Manchester | 4,753 tons |

|

Total |

14,983 tons |

Full details of the canal clearing depot organisation until its closure in November 1944 are given later.

The School of Industrial Supervision was formed at No 216 Maintenance Unit, Sutton Coldfield, in December 1942. It was at first rather in the nature of an experiment, and it was thought that such facilities as could be made available at a school would prove to be of great assistance in improving the knowledge of personnel within No 40 Group and tend to increase their efficiency, which was being jeopardised by the poorer class of labour then becoming available. The panel of lecturers at the school was composed of both Service and civilian specialist personnel, and the school itself was in the charge of a Commandant of the rank of Flight Lieutenant, but this was later upgraded to the rank of Squadron Leader.

At the end of 1942 the following units were being administered by No 40 Group: -

7 Aircraft Equipment Depots (AEDs).

6 Ground Equipment Depots (GEDs).

6 Barrack and Clothing Depots (B and CDs).

15 Equipment Parks (EPs).

2 Mechanical Transport Units (MTUs).

1 Marine Craft Storage Unit (MCSU).

2 Mobile Equipment Parks (MEPs).

2 Miscellaneous Units.

The Year of Internal Reorganisation

The expansion of the Group continued during 1943, though not on such a vast scale as that during 1942. A number of small miscellaneous units were formed and disbanded during the year and much attention was directed to internal reorganisation with a view to improving efficiency.

On 16 April 1943 No 209 Maintenance Unit at Broughton was formed and this proved to be the last of the equipment parks. No 55 Maintenance Unit at Holywood was disbanded with effect from 13 June 1943, and its functions were absorbed by No 217 Maintenance Unit at Ballymena. Prior to March 1943 the equipment parks were serving operational stations only with the airborne ranges of spares, but with effect from that month arrangements were made for them to take a regional load covering all the AED and GED requirements of stations in their areas. The post of the officers commanding parks was upgraded in November 1943 to the rank of Squadron Leader.

When originally formed the ground equipment depots served areas similar to those served by the affiliated aircraft equipment depots, but in 1943 the areas served by the GEDs in the Midlands and northern parts of England were rearranged so as to give better distributing facilities. The post of the officers commanding GEDs was upgraded in July 1943 to the rank of Wing Commander. The last of the GEDs, No 225 Maintenance Unit, Warminster, was formed on 1 June 1943 and the unit was stocked progressively.

To meet the heavy receipts and issues of marine craft a second marine craft storage unit, No 238 Maintenance Unit, was formed at Tewkesbury on 26 April 1943.

The Balloon Centre at Chessington was transferred to No 40 Group on 15 April 1943 and the accommodation was utilised as a sub-site of No 3 Maintenance Unit. Mechanical transport vehicles and components, engines and propellers and other miscellaneous items were held there on behalf of Milton. With effect from 9 November 1943, however, the sub-site took the form of a separate unit bearing the title of No 240 Maintenance Unit. Certain balloon centre accommodation at Norton and Bishopbriggs was transferred to No 40 Group during May 1943 and the accommodation thus made available was used by Nos 35 and 14 Maintenance Units respectively for the storage of mechanical transport vehicles, components and other miscellaneous equipment. In October 1943 Bishopbriggs was given the title of No 239 Maintenance Unit with independent status. Similar action was taken in respect of the accommodation occupied at Norton when in December it assumed the title of No 241 Maintenance Unit.

The only lettered maintenance units remaining at this time were the barrack and clothing depots, and in order to accord with the policy of identifying maintenance units by numbers the depots were given the following titles with effect from 1 December 1943

'A' Maintenance Unit, Wembley, became No 212 Maintenance Unit.

'E' Maintenance Unit, Newport, became No 214 Maintenance Unit.

'H' Maintenance Unit, Dumfries, became No 220 Maintenance Unit.

'R' Maintenance Unit, Glossop, became No 221 Maintenance Unit.

'S' Maintenance Unit, Nottingham, became No 227 Maintenance Unit.

'T'Maintenance Unit, Wakefield, became No 230 Maintenance Unit.

A number of mobile air stores parks were formed within the Group during 1943 for employment with the Allied Expeditionary Air Force. Nos 229 and 228 Maintenance Units were transferred to the 2nd Tactical Air Force with effect from 6 April and 29 November 1943 respectively. Further parks were also transferred on the following dates: -

No 402 Air Stores Park transferred to No 83 Group on 21 May 1943.

No; 404 Air Stores Park transferred to No 83 Group on 4 June 1943.

No 406 Air Stores Park transferred to No 83 Group on 7 August 1943.

No 206 Maintenance Unit (Polish ASP) transferred to No 84 Group on 15 September 1943.

Thus, apart from the units which had been disbanded during the year, and those formed and transferred to the Allied Expeditionary Air Force, No 40 Group were administering a total of 44 units at the conclusion of 19483as follows

7 Aircraft Equipment Depots (AEDs).

7 Ground Equipment Depots (GEDs).

6 Barrack and Clothing Depots (B and CDs).

15 Equipment Parks (EPs).

4 Mechanical Transport Units (MTUs).

2 Marine Craft Storage Units (MCSUs).

3 Miscellaneous Units.

Note. - The canal clearing depots were operated as sites of adjacent maintenance units and are therefore not shown separately in the above list.

The Introduction of the Three Regional Maintenance Wings

When Maintenance Command in February 1941 put forward their two alternative proposals for the decentralisation of control in No 40 Group they had strongly recommended the adoption of the three wing organisation on the grounds that it would result in greater control, reduced contact and correspondence, and an all-round improvement in efficiency. Their opinions, however, were overruled by the Air Ministry and the alternative seven wing organisation was adopted (see above). It was not until 25 August 1944 that it was finally agreed that the seven wing organisation was unsatisfactory and that a reduction in the number of wings to three should be brought about.

Instructions were therefore issued for the formation of Nos 55, 56 and 57 (Maintenance) Wings as follows :-

| Maintenance Wing Headquarters | Location | Date of Formation | Parent Unit |

| No 55 | Municipal Buildings, Derby | 9 September 1944 (as reorganised) | No 99 MU |

| No 56 | RAF Station, Annan | 4 September 1944 | No 14 MU |

| No 57 | Molton House, Milton | 28 August 1944 | No 3 MU |

The three wing headquarters were formed to a provisional establishment authorised by Air Ministry, and were superimposed on the existing seven (Maintenance) Wings and No 55 (Barrack and Clothing) Wing organisation.

During the period between the date of formation and 1 October 1944, the staff available was limited to a few senior officers only who carried out a survey to determine the final requirements of the new formations. No executive control was exercised by the new formations during this interim period.

The existing seven wing formation was dissolved on 6 November 1944, leaving Nos 55, 56 and 57 (Maintenance) Wings permanently established in their respective geographical regions, each being responsible to No 40 Group for its complement of maintenance units.

Miscellaneous Units

The expansion during 1944 was not so marked as in the two preceding years, no major units were formed or disbanded, but to some extent administration was made more difficult by the acquisition of storage accommodation at vacated airfields and stations thrown up as a result of the disbandment of Balloon Command.

A small Service detachment was established at the offices of the British Tabulating Machine Company at Cirencester in May 1944, for the purpose of preparing tabulated statements of shipments to overseas Commands. This was given the title of 'RAF Detachment', and was placed directly under the administrative control of Headquarters, No 40 Group.

An Airborne Forces Parachute Servicing Section was formed at Marham in June 1944 to meet the increasing commitments for all types of parachutes, in particular those required for supply dropping purposes. The aircraft hangars at Marham were taken over for the detachment which was in the first place established on the adjacent equipment park (No 89 Maintenance Unit, Barton Mills). It was subsequently found that this establishment was administratively unsatisfactory, and all the remaining accommodation at Marham, together with the parachute detachment, was taken over by No 25 Maintenance Unit as a sub-site to that depot.

The Balloon Centre at Kidbrooke was severely damaged by flying bombs in June 1944, and in order to make good the accommodation lost and to provide adequate facilities for the maintenance of the balloon barrages, it was decided by the Air Ministry that No 240 Maintenance Unit at Chessington should be evacuated by No 40 Group immediately. The dispersal of stocks from Chessington at short notice presented a problem of some magnitude as heavy loads were at that time being borne by the southern maintenance units. However, the accommodation was cleared and handed back to Balloon Command with effect from 15 July 1944.

No 40 Group Detachment, Lyneham, was formed on 15 August 1944, its function being to receive from maintenance units and contractors the equipment destined for despatch by air to all theatres. This did not include the 'AOG' requirements of overseas Commands.

The programme for the disbandment of Balloon Command was announced during September 1944. In general this provided for the return of surplus equipment within Balloon Command to certain selected balloon stations which, on completion of stocking, would be transferred to No 40 Group together with the working parties. The accommodation at numerous vacant airfields was progressively becoming available for storage purposes, and as no new construction could be contemplated vacated stations and balloon centres were the only sources of immediate extra accommodation. Details of these will be found under the heading 'The Shortage of Equipment Storage.'

In 1943 a nucleus forward equipment unit had been formed at No 3 Maintenance Unit for issues to the 2nd Tactical Air Force. This nucleus was later formed into the base maintenance unit and located at Stapleford Tawney, under the control of No 85 Group. It was intended that the base maintenance unit should move to the Continent to maintain the air forces located there, and this unit was, therefore, transferred to Bicester and renamed the Forward Equipment Unit (FEU). All equipment, with few exceptions, which was consigned to units of the 2nd Tactical Air Force was forwarded through this FEU. In addition, the FEU was progressively stocked in readiness for its projected move to the Continent and where possible it met demands from the stocks so accumulated. However, it was finally decided that the FEU should not move to the Continent but should remain in the United Kingdom and supply from there the requirements of the air stores parks operating on the Continent. It was suggested by Headquarters, No 40 Group that the existence of a unit such as the FEU, as then constituted, was both uneconomical and undesirable, and the following alternatives were recommended for consideration

(a) That the FEU should be disbanded and its functions absorbed into No 40 Group.

(b) That the storage functions of the FEU, as distinct from transit, packing and despatch, should be absorbed by No 40 Group and that the FEU should remain merely as a transit centre, with packing functions sufficient to prepare equipment for despatch according to their route.

It was agreed at a meeting held at the Air Ministry on 25 December 1944 that the FEU should be reconstituted as a transit centre under the control of No 57 Maintenance Wing in No 40 Group. This became effective on 1 January 1945 when the FEU assumed the title of No 246 Maintenance Unit. In May 1945 No 40 Group comprised

7 Aircraft Equipment Depots (AEDs)

7 Ground Equipment Depots (GEDs)

6 Barrack and Clothing Depots (B and CDs)

15 Equipment Parks (EPs)

4 Mechanical Transport Units (MTUs)

2 Marine Craft Storage Units (MCSUs)

2 Miscellaneous Units (including No 246 Maintenance Unit).

The Types of Equipment Depots In 1945

The main types of depots in use in May 1945 and their functions were briefly as follows: -

(a) Aircraft Equipment Depots (AEDs). All these depots (with the exception of No 3 Maintenance Unit, Milton) were planned to accord with a policy of dispersal and consisted, therefore, of a headquarters site and six or seven separate sites, one to three miles apart. Each contained four or more storage sheds which were generally of three types.-

(i) Fully protected, of stout concrete and steel girder construction in two sizes, approximately 56,000 square feet and 4,000 square feet in area respectively.

(ii) Semi-protected, having reinforced concrete walls with roofs of cement asbestos sheeting. The area of these was 56,000 square feet each.

(iii) Unprotected, lightly constructed of cement asbestos sheeting on steel frames with cement asbestos roofs. Their area was normally 40,000 square feet.

Diagram 18 - A Summary of the Growth of Units within No 40 Group 1939-1944

| Nature of Unit |

Feb 1939 |

Sept 1939 | Dec 1939 | Dec 1940 | Dec 1941 | Dec 1942 | Dec 1943 | Dec 1944 |

| Stores Depots | 3 | 2 | 2 | |||||

| Miscellaneous | 7 | 5 | 7 | 8 | - | 2 | 3 | 1 |

| Aircraft Equipment Depots | - | 5 | 6 | 6 | 7 | 7 | 7 | 7 |

|

Barrack and Clothing Depots |

- | 3 | 3 | 6 | 5 | 6 | 6 | 6 |

| MT Companies | - | - | - | 3 | 8 | - | - | - |

| Equipment Parks | - | - | - | - | 7 | 15 | 15 | 15 |

| MT Units | - | - | - | - | 2 | 2 | 4 | 4 |

| Marine Craft Storage Units | - | - | - | - | 1 | 1 | 2 | 2 |

| Mobile Equipment Parks | - | - | - | - | - | 2 | - | - |

| Ground Equipment Depots | - | - | - | - | - | 6 | 7 | 7 |

| Totals | 10 | 15 | 18 | 23 | 30 | 41 | 44 | 42 |

Note: In addition to the above, the FEU, Bicester, was absorbed by 40 Group with effect from 1 January 1945 on which date the unit was renamed No 246 MU.

These depots stored aircraft spares and airborne equipment from complete engines to sparking plugs; there was one 10-ton electric crane in each depot, situated in the transportation shed on the headquarters site, and a number of 2-ton electric cranes were situated strategically about the depot. There were two or more 2-ton hand cranes in most of the storage sheds. All these depots had a direct main line railway connection. The workshops were used primarily for the manufacture of special packing cases, for the repair and overhaul of the depots' transport vehicles, and for the minor repair of equipment received from contractors in a damaged condition or returned from units in a similar state. All other repair work was carried out by No 43 Group and the Civilian Repair Organisation. The depot workshops also incorporated in existing stocks of equipment the modifications subsequently received from the contractors who were embodying these improvements in their current deliveries, and were also responsible for making serviceable equipment which had deteriorated in store, and for periodical inspection of engines, magnetos, etc., etc.

(b) Ground Equipment Depots (GEDs). These depots housed the non-airborne technical equipment, such as cordage, dopes, mechanical transport spares, tools, etc. There were seven of these depots, one under hirings and one at an ex-balloon centre. The remainder were specially situated in wooded country and comprised approximately 40 dispersed sheds which were lightly built steel-framed buildings, walled and roofed with corrugated iron, and each had a gross area of 7,500 square feet or a total area of 300,000 square feet per depot.

(c) Equipment Parks (EPs). There were 15 equipment parks functioning in May 1945. Each held all stores, with the exception of the barrack and clothing items, required by the units in their supply areas. No 217 Maintenance Unit, Ballymena, was the exception as, due to its location, it held a more or less universal stock, including clothing. No 210 Maintenance Unit, Romsey, was manned predominantly by WAAF personnel, and the unit was commanded by a squadron officer. The policy at that time was to make equipment parks self-accounting, and this was being carried out progressively, although it did not apply to all the 15 parks.

(d) Barrack and Clothing Depots (B and CDs). There were six depots of this type all in hirings, such as exhibition buildings, skating rinks, factories and cinemas, and they held only uniform and clothing both for the RAF and WAAF, anti-gas clothing and barrack stores, and ground fire-fighting equipment.

(e) Mechanical Transport Reception Depots (MTRDs). These units acted as mechanical transport storage depots and supplemented the holdings at the aircraft equipment depots. A large proportion of the stored reserve was held at the aircraft equipment depots and their dispersed mechanical transport sites.

(f) Marine Craft Storage Units (MCSUs). One unit on the south-west coast of Scotland maintained the reserves of RAF marine craft. The major repairs to marine craft were effected by its parent unit of No 43 Group. A similar MCSU. was also opened at Tewkesbury.

The Shortage of Equipment Storage'

In December 1940 Maintenance Command became very concerned with the growing shortage of equipment storage and the high proportion of the storage in use which was situated in industrial target areas.

Of the eight and a half million square feet of storage space employed at that time, some one and a half million square feet was situated in industrial areas such as London, Newport, Sheffield and Manchester. Three per cent of the storage had already been destroyed at Coventry and further space had been made untenable in London as a result of enemy action. It was therefore feared that if the enemy continued the concentrated attacks on industrial towns there would be a serious risk of further losses in stocks and buildings. It was true that stocks were generally lost with the buildings and therefore ceased to become a storage problem, but deliveries off contracts continued and had to be diverted elsewhere until the lost storage was replaced. No such reserve storage had been provided to cover this.

As regards the future storage position, additional space was required for the proposed expansion and for the large number of American types which were coming into service. It was impossible to calculate exactly the storage volume required owing to the thousands of items involved, each differing in shape and size and whose future rates of consumption were unknown. Some indication could, however, be obtained by comparing the ratio of the existing first line strength with that of the proposed expansion whilst at the same time taking into consideration certain factors enumerated below.

It was understood that the expansion contemplated an increase of 228 squadrons plus a number of operational training and ancillary units, by June 1942. This represented approximately a 100 per cent increase on the existing first-line strength, including overseas Commands. However, it did not follow that the increase in equipment holding would be in direct proportion because the existing holding of many items was far below the reserve originally authorised and it was reasonable to anticipate that in the future overseas Commands would receive certain ranges of spares direct from American and Dominion industry. It was also possible that equipment depots would be by-passed, at lest in part, by the development of the method of direct supply of difficult spares from contractor to consumer. On the other hand there were many new types of aircraft coming into service for which stocks would have to be built up, whilst the spares held for old types would still require to be retained to cover training and overseas requirements. Enormous quantities of barrack and clothing stores were being purchased to cover the expansion and possible future expeditionary forces, and this would have to be stored until required. The new dispersal policy also meant additional space and as already mentioned there was a need for reserve storage to replace that lost by enemy action.

Bearing in mind that the existing equipment storage was already congested, it was considered that approximately a 50 per cent increase in storage area would be required by June 1942. It was therefore recommended that the figure of three and a half million square feet be accepted on the additional space required, but that the position should be continually reviewed and adjusted in the light of future experience.

To meet this requirement there was approximately 200,000 square feet vacant in existing storage. One and a half million square feet was under construction at Handforth and other equipment depots; and a number of civil premises were being taken over as depositories for overflow stocks. Properties suitable for storage were becoming increasingly difficult to find in safe areas, and although every effort was being made to search for them, including underground mines and disused tunnels, it was not anticipated that more than a million square feet would be obtained by this means.

This meant that a further million square feet would have to be provided by building and it was considered that a seventh universal equipment depot should be constructed in the Wellingborough area in time to be completed and stocked prior to June 1942.

A summary of the storage position at that time is as follows

| Storage in use | 8 million square feet |

| Storage under construction | 1½ million square feet |

|

Further storage to be found in hired premises in safe areas |

1 million square feet |

| Storage to be constructed (new UED at Wellingborough) | 1 million square feet |

| Total storage required by August 1942 | 12 million square feet |

With regard to the 1½ million square feet of storage in use in industrial target areas, it was considered this risk should not be accepted and that alternative storage should be provided to enable units in these areas to be vacated as soon as possible. It was suggested that this provision should be made by building six lightly constructed equipment dispersal depots in safe areas and relying upon wooded country, dispersal and camouflage for their protection. Each depot would be within forty miles by road of a universal equipment depot (UED) to reduce transportation and enable the workshop facilities of the UEDs to be shared. The parent UEDs which were provisionally selected were Nos 3, 7, 25, 16 and 35 Maintenance Units. The estimated cost of each unit was £107,000.

However, Air Ministry were opposed to the idea of constructing another universal equipment depot because on investigation it was found that such a depot would take at least two years to build and it was unlikely that Cabinet permission would be forthcoming for the necessary labour and materials. Good progress was being made with the construction of the seventh UED at Handforth, and it was therefore decided to construct the proposed equipment dispersal depots (EDDs) and make up the deficiency for the time being by increasing the number and capacity of the hirings. By November 1941 four of these EDDs were under construction, whilst the existing storage space at that time was: -

| UEDs | 7,168,000 sq feet. |

| Hirings | 509,000 sq feet. |

| B and CDs | 3,613,000 sq feet. |

| Equipment Parks | 80,000 sq feet. |

|

Total |

11,370,000 sq feet. |

It was estimated that 5 per cent of this area was vacant and that racks and bins were 85 per cent full.

In addition to this there was 1,000,000 sq feet under construction in the form of equipment dispersal depots, which together with 426,000 sq feet under acquisition or earmarked for hirings or equipment parks made a grand total of 12,796,000 sq feet.

The Air Ministry had calculated that on the basis of proportionate expansion of the Air Force an additional 10,000,000 sq feet would be required by July 1943, and that this would be required at the rate of approximately 5,000,000 sq feet a year. Deducting 1,138,000 sq feet of vacant space from the total of existing storage and adding 5,000,000 sq feet for the year's requirements brought the total required by July 1942 to 15,232,000 sq feet. With a total of 12,796,000 sq feet already existing or earmarked this left some 2,436,000 sq feet still to be found by July 1942.

When it was decided to develop the universal equipment wings in June 1942 it became necessary to convert the equipment depots and to increase their number to seven. An aircraft equipment depot (AED) was required in the London area and this need was met by hiring 60,000 sq feet at the White City. This brought the total number of AEDs to eight.

The actual storage space in use by September 1942 was 13,668,000 sq feet with 435,000 sq feet still to be constructed at the new ground equipment depots at Sutton Coldfield and Warminster.

By March 1943 the position was as follows

| AEDs | 7,529,658 sq feet. |

| GEDs | 1,576,640 sq feet. |

| B and CDs | 5,446,105 sq feet. |

|

In use Total |

14,552,401 sq feet. |

Under Construction: -

| AEDs | 2,100,000 sq feet. |

| GEDs | 615,000 sq feet. |

|

Grand Total |

17,267,401 sq feet. |

Whilst in May 1943 it was

| AEDs |

9,264,800 sq feet. |

| GEDs | 1,629,820 sq feet. |

| B and CDs | 5,902,590 sq feet. |

| Forward Holding Units | 273,410 sq feet. |

| MT Reception Depots | 57,000 sq feet. |

| MT Storage Sites | 30,000 sq feet. |

|

Total |

17,157,620 sq feet. |

Under Construction or approved

| AEDs | 2,121,500 sq feet. |

| GEDs | 680,000 sq feet. |

|

Grand Total |

19,909,120 sq feet. |

The storage area available for the aircraft equipment depots in March 1944, including that under construction or approved, was 12,523,590 sq feet. This area together with the 2,486,570 sq feet in use at ground equipment depots and the 6,066,740 sq feet at barrack and clothing depots made a grand total of 21,076,900 sq feet.

Although it had been thought that provision had been made up to September 1944, the accumulations of stock during the first half of 1944 had exceeded the forecast figure, and in consequence a thorough investigation was made by Maintenance Command into the future storage requirements for the period ending 30 June 1945. From this it was estimated that approximately 7,000,000 sq feet of space (or the equivalent of four AEDs) would be needed, and of this at least 50 percent would be required by September 1944. In the time available, construction would have been out of the question and it was recommended that accommodation for this phase should be provided by additional hirings or the release of Service accommodation. This survey was followed by a meeting held at Air Ministry on 21 June 1944 at which it was agreed that some reduction in the estimates could be made on the reasonable assumption that the clearance of redundant stocks would be accelerated. The storage requirements for the period were therefore reduced to 6,000,000 sq feet, and as new construction could only be undertaken to a very minor extent (60,000 sq feet) almost all the space would have to be provided in premises already constructed, e.g. redundant aerodromes thrown up by other Commands.

By June 1944 additional hirings and completion of buildings in hand had raised the total storage area to 21,765,000 sq feet, but the position was becoming acute and was likely to get worse. The possibilities of arranging extensive open-air storage were explored, in order to ensure the best use of the limited covered accommodation available. It was decided that equipment suitable for storage in the open should be scheduled by sub-committees and the scheme was commenced in November 1944.

By the end of December 1944 the storage area for the aircraft equipment depots had increased to 14,029,923 sq feet, chiefly as a result of the allocation of some fifteen redundant RAF stations with a total storage capacity of 1,486,484 sq feet. The ground equipment depots showed a slight increase to 2,583,543 sq feet whilst the barrack and clothing depots were reduced to 5,860,328 sq feet. However, the grand total of 22,473,794 sq feet for all types of depots represented an increase over the June figure of 1,396,894 sq feet.

At a meeting held at Maintenance Command Headquarters on 8 January 1945, various proposals for increasing the storage accommodation within No 40 Group were considered, but owing to the fact that all labour for major building projects during the year had already been allocated the only forms of additional storage for which there was any hope were as follows

(a) The provision of additional equipment dispersal depot sheds by Air Ministry.

(b) The erection of blister hangars under local Command arrangements.

(c) The use of hard standings already available at airfields in the form of runways and dispersal points, etc.

It was not anticipated that it would be possible to lay hard standings at the aircraft equipment depots owing to the lack of labour, but this was subsequently overcome, at least in part, by the use of old railway sleepers. The Command were, in fact, faced with the prospect of an increasing number of scattered storages all over the country with all their attendant difficulties. Meanwhile, the shortage of covered accommodation continued and in February 1945 the Secretary of State for Air decided that immediate steps should be taken to dispose of large quantities of technical equipment which the Air Ministry provisioning branches had declared to be surplus to future requirements. It was estimated that when this clearance had been effected over 2,000,000 sq feet of badly needed covered storage would become available. A high priority was therefore accorded to the task, additional personnel and MT vehicles were established at each aircraft equipment depot and the Ministry of Aircraft Production were approached with a view to the establishment of an additional Metal Produce Recovery Depot in the South of England.

By this time it had become apparent that the war in Europe was reaching its closing stages and discussions accordingly centred on such matters as post-war policy within the Group and the arrangements which would have to be made for the reception and disposal of equipment from stations closing down.

The Dispersal of Stocks at Equipment Depots

The principle of holding a universal range of all classes of stores at each equipment depot afforded a large measure of dispersal and this was further increased by the layout in the newer types of depot which provided for six widely separated sites, each site consisting of four to five fully protected and non-protected large-size sheds. In addition there were a number of fully-protected smaller sheds on each site for valuable stores. It had been the practice in the past to store one item of equipment in one building only, with the exception of the stock of aero-engines, which had been split between two sites.

By the end of 1940 it was realised that with enemy bases so much nearer, enemy aircraft could approach the depots from the west and south, thereby, increasing the threat of attack and rendering the original plan of dispersal inadequate. The ideal, from a security aspect, would have been to hold a comprehensive range of items on each depot site, so that if a number of sheds were destroyed only a small portion of each item would have been lost and issues to units could have been continued. This, however, would have been impracticable, as the administrative difficulties of keeping trace of such widely separated stocks and maintaining an equal division between sites would have outweighed the greater security which would have been afforded.

Further dispersal and protection of stocks was, however, possible and indeed essential, especially with regard to the more important items which would have been most difficult to replace, and in October 1940 steps were taken to provide for this on the following lines: -

(a) Splitting stocks between sheds and sites as far as possible without seriously compromising the control over the receipt and issue. For example, by dividing the important ranges of aircraft equipment between two sites and spreading aero-engines and airscrews throughout every protected shed in each depot, main aircraft components were also dispersed into a number of protected sheds.

(b) Dispersing stocks within sheds by splitting the stock of individual items into groups scattered around the sheds.

(c) By protection within the sheds using sandbags, heavy cases, bins and even some of the stouter items of equipment themselves to form traverses of the more vulnerable items against damage by splinters. Asbestos screens were also provided to divide sheds holding inflammable stores, so that a fire could be isolated.

(d) Storage in the open was not satisfactory for many types of stores but where this was possible it was done by forming dumps between sheds and camouflaging. This was considered to be a perfectly suitable method of storage for such items as galvanised hardware, drummed oil and other similar stores; MT vehicles were also stored where there was natural tree cover within the depot boundaries, and where this did not exist they were stored in sheds throughout the depot.

(e) By dispersion to local depositories and garages of large stocks of items for which there was little turnover.

(f) Protection of personnel by the construction of sandbag shelters within the sheds for use in the event of a surprise attack.

(g) Additional precautions were also taken to protect all fire-fighting appliances and petrol points with sandbags. Repair materials and tarpaulins were also held in readiness so that temporary repairs could be made at once to damaged sheds, thus preventing further damage to stocks due to exposure. Large concentrations of stocks awaiting unloading were also avoided by dispersal throughout the depot lines at nightfall.

The work of dispersing equipment was given a high priority, but progress was handicapped by the acute shortage of storage space in the Group and the difficulty which was experienced in acquiring outside depositories.

Stock Control and Provisioning

In May 1939 the dispersal of stocks held at the stores depots to the new universal equipment depots was commenced. The dispersal was arranged and carried out in a hasty manner with the result that for some time afterwards no exact stock figures existed for the depots.

With the total stock of any particular item divided between a number of depots the need arose for some form of consolidated stock record. These data were required by the central provisioning branches and also as a means of matching demands to the depots holding the necessary stock. It was therefore decided to form Master Provision Offices (MPOs). After some unsuccessful attempts at devising a procedure which would provide the MPO with the information in the manner and with the speed desired, the posting slip was introduced in October 1939. This method of informing the MPOs of receipts and issues of stocks at the individual depots remained in force throughout the war with the exception of those vocabulary sections which became mechanised.

The rapid expansion of the Royal Air Force, coupled with the increase in the range and number of items being provisioned necessitated a corresponding increase in the number of master provision offices. The number of MPOs and the respective number of items provisioned by them in April 1945 were as follows: -

|

Type of spares provisioned |

No of MPOs | No of items provisioned |

Total |

|

| Active | 'Current Supply' | |||

|

Airframe spares |

3 | 56,614 | 185,291 | 241,905 |

|

Engines and engine accessories |

1 | 34,700 | 16,700 | 51,400 |

|

Radio, electrical and armament spares |

1 | 87,300 | 9,700 | 97,000 |

|

Misc. airframe spares and AGS |

1 | 21,601 | 26,394 | 47,995 |

|

Tools and materials |

1 | 4,955 | 4,358 | 9,313 |

|

MT spares |

1 | 31,905 | 135,095 | 167,000 |

| Barrack and clothing | 1 | 14,127 | 5,401 | 19,528 |

| American spares and equipment | 1 | 60,356 | 118,766 | 179,122 |

|

Totals |

10 | 311,558 | 501,705 | 813,263 |

In December 1940 provision scheme 'A' was published. This was the first of the provision schemes designed to provide an automatic method of reviewing every item of equipment twice each year, and items which were sufficiently 'active' once each month. This ensured adequate forward cover on contract. The scheme was initially applied to airframe spares but subsequently was extended to cover other types of equipment. The basic principles of scheme 'A' were, however, retained, although minor modifications were necessary to meet the particular requirements of individual vocabulary sections.

Early in the war it was decided that the duplication of accounting caused by the maintenance of the main stock ledgers was unnecessary and should be discontinued. In July 1940 the storehouse 'tally cards' were withdrawn from the storehouses and centralised in the unit headquarters building, where they were maintained by clerical staff employed in the newly formed stock recording section. The stock recording section was housed in close proximity to the demand control officer and these two sections were later amalgamated under the chief equipment officer to form the stock control office. In the same year, 1940, the schedule of requirements and issues (Form 1368) was introduced.

This form was designed to provide a schedule of demand which could be readily duplicated by the Fordigraph process. It enabled a number of sets of issue vouchers to be raised from the same original 'Master' demand form, and also any number of advice copies, without the need for re-typing the demand. In June 1941 this form was issued in various colours to enable the copies used for specific purposes to be easily recognised.

The Revised Depot Procedure

A great deal of work was done in investigating the problem concerning No 40 Group and it soon became clear that there was no short cut or simple solution to these problems. The Directorate General of Equipment, Headquarters, Maintenance Command and No 40 Group all co-operated in an endeavour to find workable solutions.

The experience gained from operating equipment depots in the early years of the war showed clearly that the organisation of a depot should be such as to ensure that: -

(a) Equipment was received, unpacked and brought on charge quickly, so that it could be available for reissue at the earliest possible moment.

(b) Available equipment was issued as quickly as possible to meet demands.

(c) All transactions were recorded accurately and the master provision officers (MPOs) advised without delay of all transactions.

(d) Within the minimum limitations imposed by the needs of the essential systems the organisation should be made to work with the least possible number of staff.

Investigation of the two aims contained in paragraphs (a) and (b) above was carried out in the summer of 1942. A review of existing methods of bringing on charge and issuing equipment was undertaken, and after detailed discussions had taken place with all concerned revised systems were prepared.

The bringing on charge system had been in operation at the Hartlebury depot, in one form or another, for nearly a year and the revised system was introduced in June 1942. The main essential of the new system was that the stores inwards book and the site receipt voucher registers' were combined. The major part of the depot internal transit sheets was eliminated and the compilation of two separate handwritten records avoided by the use of carbon copies. The introduction of an additional copy for the use of a small progress section was also a new feature and was designed to ensure the expeditious passing of the vouchers to stock records (to bring on charge) and to accounts (to release paper for the payment of bills).

A revised system of issuing was also introduced at Hartlebury at the same time. This was based on the principle of issuing the equipment first and recording it afterwards, or the exact opposite of the normal method. A loose-leaf issue voucher register was also introduced with a view to avoiding the preparation of three separate handwritten documents. It was claimed that as the system depended on the application of the demand to the actual equipment in the bins it would ensure that such equipment as was available would be issued and, moreover, that a type of selective stocktaking of those items in constant demand would be achieved. Statistics substantiated this belief by showing up discrepancies which under the old system would not have been revealed.

In November 1942 these revised procedures were introduced at all the equipment depots.

Mechanised Stock Recording

In November 1943, Hollerith punched card machines were installed at No 25 Maintenance Unit, Hartlebury. The supply of these machines was, however, limited and it was not until February 1945 that the last machines required to equip all the aircraft equipment depots were received.

The principle underlying the use of the machine was that a card was punched for every movement of stock. The relative details of receipts or issues were punched in code, and these included the section and reference number, quantity, consignee, terms of issue, etc. The cards were then used to prepare the daily stock journal for the maintenance unit concerned and also the posting sheet for onward transmission to the master provisioning office.

The use of these machines reduced clerical labour, increased accuracy, and provided an easy method of obtaining statistical data for future provisioning.

The Introduction of the Three-point Distribution System

A review of the dispersal policy in April 1948 revealed that many of the difficulties which existed at that time could be directly traced to use of the seven-point distribution system. This system took no account of the allocation of the consumer units, whilst at the same time contractors were not readily able to comply with the delivery instructions given. As a result the reallocation issues from all aircraft equipment depots were some 30 per cent of their total load, thus causing unnecessary work and delays in issue.

With a view to eliminating these difficulties, economising in storage space and improving the service and standard of the personnel by reason of greater specialisation, it was decided to proceed steadily with the reduction of the dispersal of all airframe, engine and mechanical transport spares to a three holding basis. In order to implement this policy an allocation key was maintained at Headquarters, No 40 Group in order to determine the distribution on the basis of: -

(a) Home consumer units.

(b) Overseas requirements.

(c) Location of manufacturers.

(d) Location of home repairers.

(e) Embodiment loan requirements.

The total number of types to be held by each aircraft equipment depot was reduced by about 50 per cent and this ultimately gave considerable relief in storage space requirements. It was still necessary to allocate one depot in each case as the specialist or MPO depot, in order to provide for the effective handling of modification sets, overseas bond requirements, etc., and depots were selected for this purpose accordingly.

The Canal Transit Scheme

It was decided at the end of 1941 to carry out experiments in the use of inland waterways as a means of alternative transport. These experiments were conducted from January to April 1942. The object of the scheme was to save road transport, to relieve the railways, and to develop an alternative transport method which would be capable of expansion should the normal methods be hampered by enemy action.

The method employed was to assemble small batches of traffic from contractors in the big industrial areas in transit sheds on the waterside. These batches were then made up into twin barge loads for the same destination. Canal transit depots were located at London, Birmingham and Manchester. Initially the destination was the ultimate consignee and the canal carrier took the traffic straight through and made the delivery from his own wharf by road. Subsequently the delivery was made from transit depot to transit depot, the final delivery to local consignees being by road, this speeded up the turn-round of barges as it enabled them to be loaded with goods destined for more than one consignee.

The traffic for delivery to maintenance units came not only from the contracts placed by the Air Ministry and the Ministry of Aircraft Production, but also from those placed by the Ministry of Supply and Works and Buildings. The scheme was continued after April 1942 and by July of the same year it was handling approximately 1,500 tons of traffic a month by means of 40 pairs of barges.

The main fault of this means of transport was the length of time it took to reach its destination. The canal barges were slow and the numerous locks which had to be negotiated further reduced their speed. With transit times running into many weeks the Ministries became increasingly reluctant to divert from road and rail the limited class of goods suitable for this form of transport, and with this reduction in traffic the scheme died a natural death. Air Ministry authority was given for the disbandment of Nos 1, 2 and 3 Canal Clearing Depots with effect from 1 November 1944.

The three canal clearing depots shipped a total of 61,419 tons of equipment during the three years in which they were in operation and it was estimated that their closure placed 14 extra rail trucks on the railway system daily or an average of two trucks per day into each aircraft equipment depot.

The Bomber Command 'AOG' Procedure

The method used to expedite the issue of urgently required spares for Aircraft on the Ground (AOG) had proved to be very successful, but it was decided in March 1942 that the scheme needed certain modifications when used by Bomber Command stations. Trials were therefore conducted with a view to speeding up the delivery of equipment which was already available at the parent universal equipment depots and a special AOG collection and delivery service was introduced. The ultimate aim was to deliver the equipment to the consignee within 30 hours of the time the demand left the Bomber station.

These trials proved successful and on 28 May 1942 a revised AOG procedure for Bomber Command was introduced as follows: -

(a) Stations submitted theft AOG demands as they arose during the day and night by teleprinter either to the equipment park or regional depot. On receipt they were dealt with immediately on a twenty-four hour basis.

(b) A daily AOG express delivery service was maintained at each equipment depot wing. The vehicle left the depot at a fixed time each day.

(c) Arrangements were made for the immediate despatch of equipment but due regard was paid to the fact that the express delivery service could sometimes prove the speediest.

(d) In the case of partial or total inabilities an inter-depot express delivery service was maintained which linked up with the main delivery service from the depot wing. Where items were too large additional transport was provided.

Experience had shown that AOG demands had been accumulating at the station equipment sections and instructions were therefore issued to station equipment officers to give immediate clearance to signal demands as and when completed.

A priority scheme was also introduced for the signals, and station commanders were allowed to authorise immediate priority where this would enable an immediate operational requirement to be loaded on that day's express delivery.

Preservation and Pre-packing

Pre-packing as a subject was first introduced in June 1943, at which time the Starley report was being circulated. Following the publication of this report it was notified that it was the intention to apply preservation and pre-packing to mechanical transport spares. Headquarters, No 40 Group requested that they should be included in the committees then sitting in London, and suggested that what was necessary for mechanical transport spares was even more necessary for airborne equipment.

The inauguration of pre-packing, so far as the Ministry of Supply contractors were concerned, was decided upon at Chilwell in October 1943. On 28 January 1944 the first meeting of the Joint Air Ministry - Ministry of Aircraft Production Committee was held, and at that meeting it was decided to deal with the equipment in the following order of priority: -

(a) Aero-engine spares and aero-engine accessories.

(b) Radio and electrical equipment, including valves.

(c) Armament.

(d) Airframe spares.

Following meetings at Austin Works, Longbridge, and ROD, Chilweil, on 24 March 1944, at which the Director General of Equipment and Depot Commanders were present, instructions as to the policy to be pursued by No, 40 Group were issued. The work was divided into three phases: -

(a) Phase I. - This covered the preservation, packaging and identification of overseas issues to the best possible standards with the materials available at that time, and Depot Commanders were instructed to give full consideration to any form of improvisation that could be devised.

(b) Phase II. - This covered the preservation and packaging of depot stocks by outwork centres or by depot staff.

(c) Phase III. - This applied to the preservation and packaging by manufacturers before delivery to depots.

The materials were demanded, the personnel establishments prepared, and plant requirements were put in hand. However, there were many difficulties, particularly with regard to the availability of cartons and other materials, but nevertheless a total of 6,794,890 cartons were packed by No 40 Group units up to the end of 1944. The weekly output in December 1044 had reached a total of 291,951.

The Formation of the Forward Transit Centres.

The volume of work handled at the maintenance units in No 40 Group in July 1943 showed a marked increase over that handled in January of the same year. Experiments were therefore carried out within Maintenance Command with a view to finding a system which would effect economies in motor transport and man-power whilst at the same time maintaining prompt delivery.